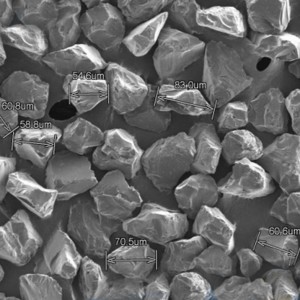

Boron Carbide F100

Boron Carbide (Boron Carbide) has a molecular formula of B4C and a molecular weight of 55.26. Boron carbide is an inorganic non-metallic high-performance structural ceramic material formed by the combination of boron and carbon under high temperature conditions. It also has functional ceramic properties. Rhombic hexahedron is one of the hardest man-made materials, second only to diamond and cubic boron nitride in hardness, Mohs hardness 9.36, microhardness 5400-6300kg/mm2, specific gravity 2.52g/cm3, melting point 2450 degrees Celsius, resistance High temperature, no chemical reaction with acid and alkali. With stable chemical properties, light weight, high hardness, semiconductor and other characteristics. Due to its high hardness, it is suitable for grinding, polishing, drilling and other processing of various cemented carbides, gemstones and other materials, and manufacturing engineering ceramic abrasive tools, precision measuring components, and engineering ceramic material products with high wear resistance, such as: High wear-resistant nozzles for aero-engines, high-precision sealing rings, aerospace vehicle surface coatings, military bullet-proof armor sheets, etc., and because the boron contained in them has thermal neutron absorption cross-section characteristics and high boron content, it is a nuclear industry reactor. The main boron-containing material for the manufacture of reaction rate regulating rods.