100% Original Factory Sic Cantilever Beam - Silicon Carbide Beam – Anteli

100% Original Factory Sic Cantilever Beam - Silicon Carbide Beam – Anteli Detail:

Product detaill:

Reaction-sintered silicon carbide square beams are applicable for load-bearing structure frames of tunnel kilns, shuttle kilns, double-layer roller kilns and other industrial kilns. The product features in that the high-temperature bearing capacity is large, there is no bend or deformation in long-term use, and the service life is several times that of other materials, thus it is the ideal kiln furniture for sanitary porcelain and other electrical porcelain industries. The product is characterized with excellent high-temperature flexural strength, thermal shock resistance, oxidation resistance and free deformation in long-term use, thus can significantly reduce energy consumption without increasing the weight of the kiln car.

Major technical indicators of reaction-sintered silicon carbide products

Characteristic:

a.High temperature strength allows heavy loading weight

b.Excellent thermal shock resistance

c.High thermal conductivity

d.Excellent oxidation resistance translates to long life under high working temperature

Application

Silicon nitride and silicon carbide beams have excellent high-temperature flexural strength, creep resistance and oxidation resistance; mainly used in sanitary ceramics, high-voltage electrical porcelain, filters, quartz crucibles; shed plates and fish-shaped plates which are widely used in daily-use ceramic Industry; protection tube is used for temperature measurement in various industries; special-shaped products and burner sleeves are widely used in various kiln and mechanical engineering.

| Item | Data | Data |

| Operating Temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Porosity | % | < 0.1 |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280 (1200℃) | |

| Elastic Modulus | Gpa | 330(20℃) |

| Gpa | 300 (1200℃) | |

| Thermal Conductivity | W/m.k | 45 (1200℃) |

| Thermal Expansion Coefficient | K-1×10-6 | 4.5 |

| Mohs Hardness | 13 | |

| Alkalinity and Acidity | Excellent |

| Length(m) | Sectional Dimensions | Concentrated Bearing Capacity(kg) | Resultant Force of Uniform Distribution Force(kg)

|

||

| L | B | H | δ | ||

| 1 | 30 | 40 | 6 | 130 | 260 |

| 1 | 40 | 40 | 6 | 165 | 330 |

| 1 | 40 | 50 | 6 | 235 | 470 |

| 1 | 50 | 70 | 7 | 526 | 1052 |

| 1 | 60 | 90 | 9 | 1059 | 2118 |

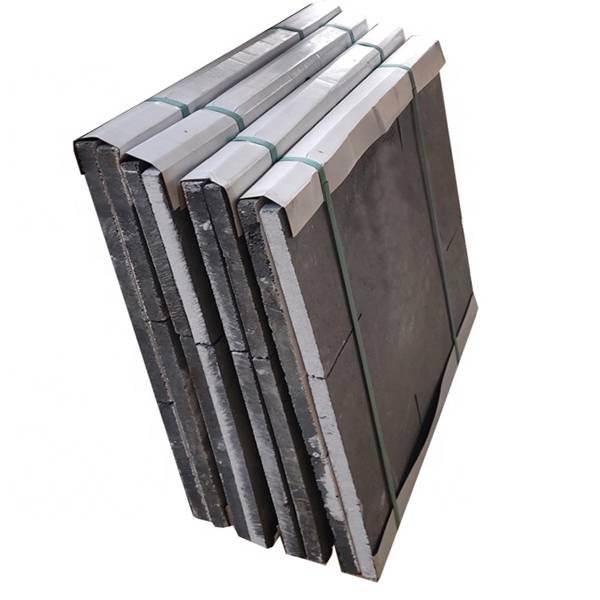

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with 100% Original Factory Sic Cantilever Beam - Silicon Carbide Beam – Anteli , The product will supply to all over the world, such as: Milan, Casablanca, Chicago, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.