Black Silicon Carbide

Performance features: black silicon carbide is made of quartz sand, petroleum coke (or coal coke), sawdust and other raw materials by high-temperature smelting in the resistance furnace, and by high-temperature smelting in the resistance furnace, which is black opaque, hexagonal crystal, Mohs hardness of 9.15. Second only to diamond and boron carbide, it is brittle, sharp and conductive

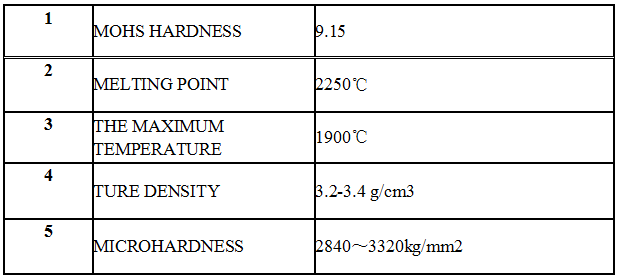

Physicochemical properties

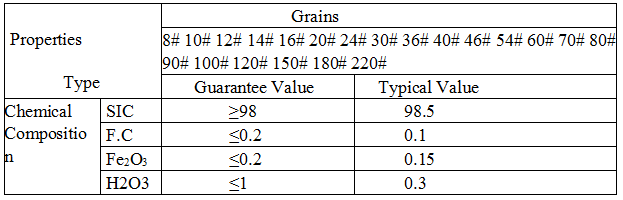

Grain size

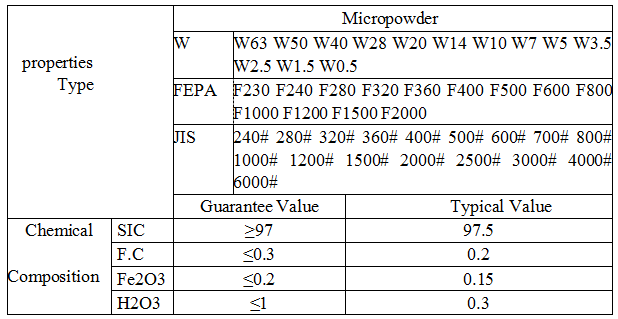

Micro powder specifications

Product use

1. Abrasives: mainly used for grinding wheel, sandpaper, oilstone, grinding head, grinding paste, monocrystalline silicon, polycrystalline silicon in photovoltaic products and surface grinding and polishing of various devices.

2. High grade refractory: it can be used as metallurgical deoxidizer and high temperature resistant material to make high temperature furnace components, supporting parts, etc.

3. Functional ceramics: it can not only reduce the capacity of kiln tools, but also improve the quality of kiln products and shorten the cycle. It is an ideal indirect material for baking and sintering of ceramic glaze, high temperature non oxide ceramics and reaction sintering ceramics.

4. Non ferrous metals: Iron and steel industry, metallurgy and mineral processing industry, have been applied.