Factory source 80%- 99.5% Silicon Carbide - Sintered Silicon Carbide Micropowder Green – Anteli

Factory source 80%- 99.5% Silicon Carbide - Sintered Silicon Carbide Micropowder Green – Anteli Detail:

Product Detail:

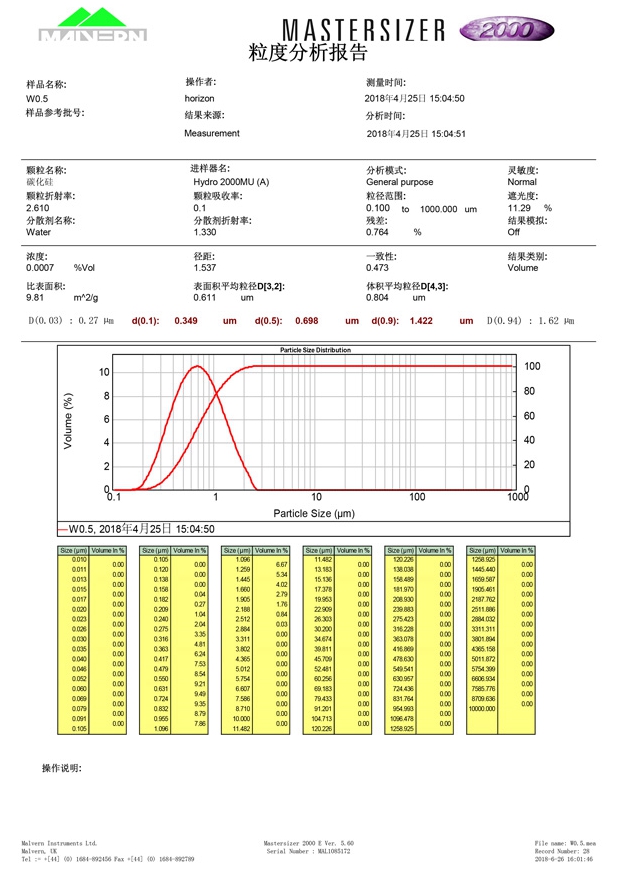

1.Micropowder GC0.5 is made of high purity silicon carbide raw material with good quality, Developed via met method

2.GC0.5 micro powder has distinct advantage such as narrow particle size distribution, good fluidity, lower heat shrinkage and large sintering density,etc.

3.The Oxygen content of this micropowder is effective controlled via using special low temperature and drying technology

Application:

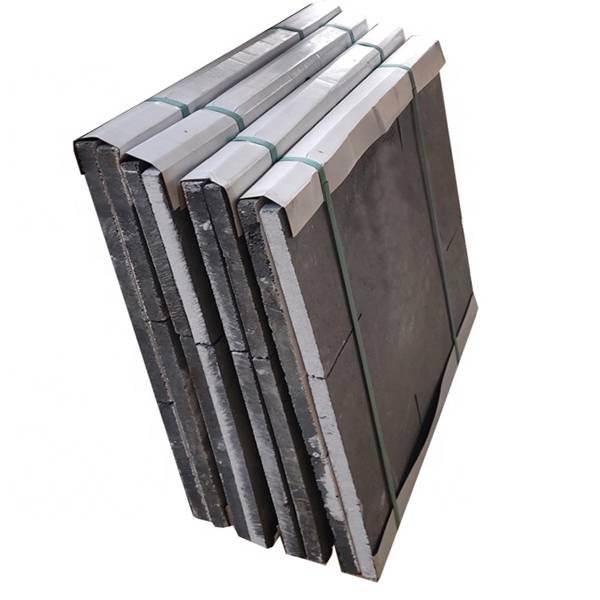

These micropowder are selling well in Japan and European markets and are widely used in the mechanical seal, bulletproof armors,chemical and petroleum and aerospace area,Heat Exchanger Tubes,Blast and Atomization Nozzles,Process Industry Valve Applications,Paper Industry Applications,Centrifuge Tiles and Wear Parts, Semiconductor Production,etc

Chemical Composition Content:

|

Model |

SiC |

Fe2O3 |

F.C |

SiO2 |

PH |

Water content |

|

W0.5 |

98.90% |

0.01% |

0.15% |

0.18% |

7 |

0.02% |

Packing:25Kg /50kg Plastic bag or Customized as Clients

Delivery time: 1*20GP container takes about 7 to 10 days

MOQ: 1Ton

Samples: If Customer needed ,Free samples available and charge shipping

Production Process:

Sintered silicon carbide (SiC) is produced by initially mixing fine (sub-micron) and pure silicon carbide powder with non-oxide sintering aids. The powdered material is formed or compacted by using most of the conventional ceramic forming processes such as die pressing, isostatic pressing and injection moulding. Following the forming stage the material is sintered in an inert atmosphere at temperatures above 2000°C. The sintered silicon carbide can then be machined to precise tolerances using a range of precision diamond grinding or lapping techniques.

Sintered silicon carbide Key Properties

1.High hardness (second only to diamond)

2.Low density 40% the density of steel – approximately the same as aluminium

3.Low porosity

4.Good wear resistance in sliding and abrasive environments

5.Excellent corrosion resistance in most chemical environments

6.Low thermal expansion and high thermal conductivity leading to excellent thermal shock resistance.

Cooperation Process for new customers

1.Communication with customers via email and phone know well about customer’s industry field and requirement on Silicon Carbide parameter.

2.We provide customers the optimum and reasonable suggestion on product model.

3.Its available to send samples or delivery in small batch to checking quality

4.After customer’s confirmation ,follow this as standard and go into production,keep some samples so that both sides can check in the future.

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Factory source 80%- 99.5% Silicon Carbide - Sintered Silicon Carbide Micropowder Green – Anteli , The product will supply to all over the world, such as: Slovenia, Jamaica, Florence, To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.