OEM Customized China High Performance Manufacturer 36grit Grit 50X915mm Silicon Carbide Grain Abrasive Sanding Belt for Knife Belt Sanders

“Based on domestic market and expand abroad business” is our improvement strategy for OEM Customized China High Performance Manufacturer 36grit Grit 50X915mm Silicon Carbide Grain Abrasive Sanding Belt for Knife Belt Sanders, Our merchandise are new and previous prospects consistent recognition and trust. We welcome new and outdated shoppers to contact us for long term small business relations, common advancement. Let’s speeding within the dark!

“Based on domestic market and expand abroad business” is our improvement strategy for China Abrasive Belt, Grinding Belt, Adhering to the principle of “Enterprising and Truth-Seeking, Preciseness and Unity”, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we have been specialized.

Product Detail:

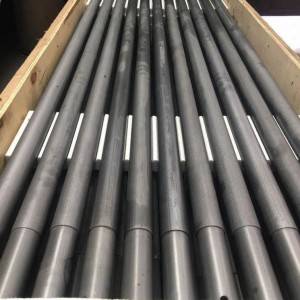

Reaction Sintered Silicon Carbide Rollers are characterized with excellent high-temperature bending strength, oxidation resistance, super wear resistance, free breaking in long-term use at a high temperature, free bending and deformation.

Application:

It can be applied to high-temperature firing zone of roller kilns for daily ceramics, sanitary porcelain, building porcelain, glass and magnetic materials. The service life is more than 10 times that of aluminum oxide ceramic rollers.

Major Technical Indicators of Reaction-sintered Silicon Carbide Products

|

Item |

Unit |

Data |

|

Operating Temperature |

℃ |

1380 |

|

Density |

g/cm³ |

≥3.02 |

|

Porosity |

% |

< 0.1 |

|

Bending Strength |

Mpa |

250(20℃) |

|

Mpa |

280 (1200℃) |

|

|

Elastic Modulus |

Gpa |

330(20℃) |

|

Gpa |

300 (1200℃) |

|

|

Thermal Conductivity |

W/m.k |

45 (1200℃) |

|

Thermal Expansion Coefficient |

K-1×10-6 |

4.5 |

|

Mohs Hardness |

13 |

|

|

Alkalinity and Acidity |

Excellent |

The Bending Strength of RBSiC (SiSiC) Roller is 250MP,safety coefficient is 5 times, and the length of bearing capacity of 1 meter. If the product length is L, the bearing capacity can be calculated with the following formula:

Concentrated Force = Surface Value 1/L, Resultant Force of Uniform Distribution Force = Surface Value *1/L. The adaptive temperature of the bearing capacity is 1380℃.

Roller Load-Bearing Capacity List

|

Length (m) |

Sectional Dimensions |

Concentrated Loading (kg) |

Uniformly Distributed Loading(kg) |

||

|

L |

D1 |

D2 |

δ |

||

|

1 |

35 |

23 |

6 |

70 |

140 |

|

1 |

40 |

28 |

6 |

97 |

194 |

|

1 |

45 |

33 |

6 |

130 |

260 |

|

1 |

50 |

38 |

6 |

167 |

334 |

|

1 |

55 |

44 |

7 |

261 |

522 |

|

1 |

60 |

46 |

7 |

283 |

566 |

|

1 |

80 |

46 |

8 |

604 |

1208 |

Packing:As requirements

Delivery time: 1*20GP container takes about 10-20days

MOQ: 5pieces

Samples: If Customer needed ,Free samples available and charge shipping”Based on domestic market and expand abroad business” is our improvement strategy for OEM Customized China High Performance Manufacturer 36grit Grit 50X915mm Silicon Carbide Grain Abrasive Sanding Belt for Knife Belt Sanders, Our merchandise are new and previous prospects consistent recognition and trust. We welcome new and outdated shoppers to contact us for long term small business relations, common advancement. Let’s speeding within the dark!

OEM Customized China Abrasive Belt, Grinding Belt, Adhering to the principle of “Enterprising and Truth-Seeking, Preciseness and Unity”, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we have been specialized.