Special Design for Silicon Carbide Grinding Types Gc2000 - Casting and Extrusion Green Reaction Bonded Silicon Carbide Micropowder – Anteli

Special Design for Silicon Carbide Grinding Types Gc2000 - Casting and Extrusion Green Reaction Bonded Silicon Carbide Micropowder – Anteli Detail:

Product Detail:

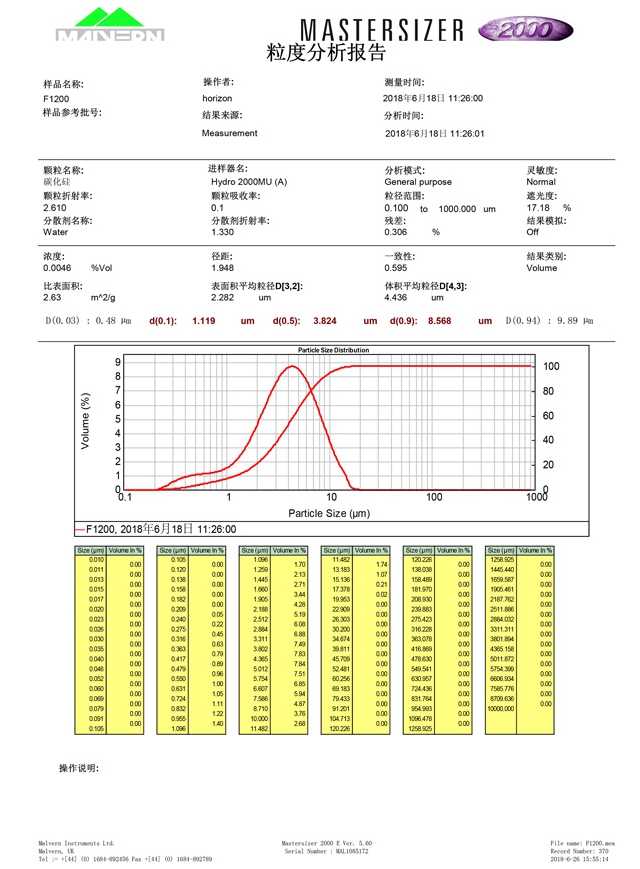

1.We produced RBSIC Micro powder such as F240,F1200,W20,W14,#90,#150 etc.

2.They have good advantages such as good fluidity,good purity, good grain ship, reasonable particles size distribution and high packing density ,etc.

3. Our RBSiC micro powder are well received by customers

Application :

Which are used in slip casting process and extrusion process of RBSIC Products, such as Kiln Furniture Beams and Supports,Rollers,Cooling air pipes,Burner Wear Parts And Thrust Bearings, Mechanical Seals And Vanes, Nozzles,Cantilevers Paddles,Spiral Nozzles,Precision Components etc.

Chemical Composition Content

|

Model |

SiC |

Fe2O3 |

F.C |

SiO2 |

PH |

Water content |

|

F240 |

99.50% |

0.06% |

0.07% |

0.08% |

7 |

0.01% |

|

F1200 |

0.9935 |

0.0003 |

0.0009 |

0.001 |

7 |

0.0002 |

|

W14 |

99.40% |

0.02% |

0.08% |

0.10% |

700.00% |

2.00% |

|

W20 |

99.40% |

0.03% |

0.08% |

0.09% |

700.00% |

0.02% |

Packing:25Kg /50kg Plastic bag or Customized as Clients

Delivery time: 1*20GP container takes about 7 to 10 days

MOQ: 1Ton

Samples: If Customer needed ,Free samples available and charge shipping

Production Process:

Reaction-bonded silicon carbide is produced by mixing SiC powder with powdered carbon and a plasticizer, forming the mixture into the desired shape, burning off the plasticizer, and then infusing the fired object with gaseous or molten silicon, which reacts with the carbon to form additional SiC.

The properties that lead to selection of the material are:

1.Resistance to wear

2.Resistance to corrosion; the material tolerates a wide range of acids and alkalis

3.Resistance to oxidation

4.Abrasion resistance

5.Good thermal shock resistance due to low thermal expansion coefficient and high thermal conductivity

6.Strength at high temperature

7.Good dimensional control of complex shapes

Cooperation Process for new customers

1.Communication with customers via email and phone know well about customer’s industry field and requirement on Silicon Carbide parameter.

2.We provide customers the optimum and reasonable suggestion on product model.

3.Its available to send samples or delivery in small batch to checking quality

4.After customer’s confirmation ,follow this as standard and go into production,keep some samples so that both sides can check in the future.

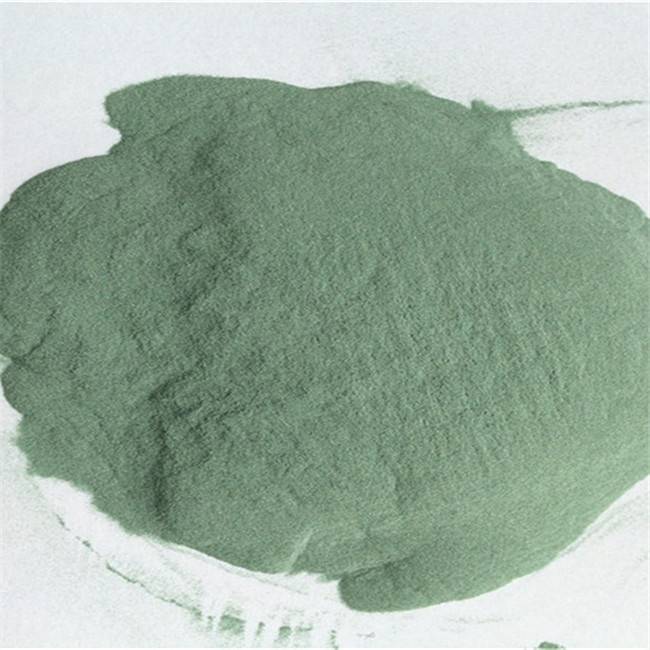

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for Special Design for Silicon Carbide Grinding Types Gc2000 - Casting and Extrusion Green Reaction Bonded Silicon Carbide Micropowder – Anteli , The product will supply to all over the world, such as: Monaco, South Africa, United States, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.