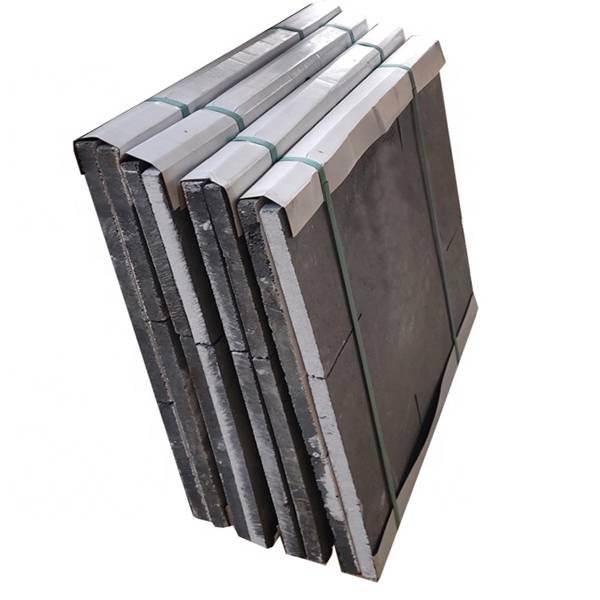

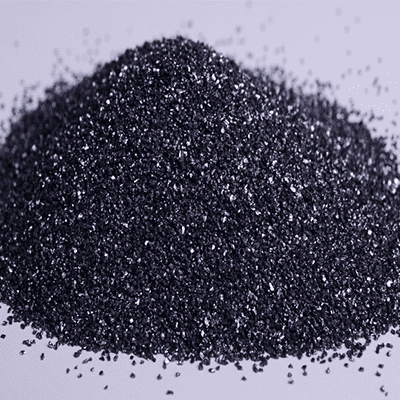

Well-designed Black Silicon Carbide Sic 95% 1-0mm - Crucible – Anteli

Well-designed Black Silicon Carbide Sic 95% 1-0mm - Crucible – Anteli Detail:

Product Description

Silicon carbide crucibles are a kind of ceramic deep bowl-type container. In case of solids to be heated on big fire, a crucible shall be used. Silicon carbide crucible is better able to withstand high temperatures than glassware, and the material in a crucible to be molten shall not be too full, to prevent the heated material from jumping out and allow air to free access to for possible oxidation reactions. Because the bottom of crucible is very small, a crucible generally needs to stand on a pipeclay triangle for direct heating on fire.

A crucible can be placed on an iron triangle in an upright or diagonal manner, and can be arranged on your own depending on the needs of an experiment. After heating, the crucible shall not be immediately placed on a cold metal table, to prevent rupture due to a sharp cooling, and it shall also not be immediately placed on a wooden table, to prevent scorching the desktop or causing a fire.

Application

Silicon carbide crucibles are mainly used in metallurgy, casting, machinery, chemical and other industrial sectors, and are widely used for smelting of alloy tool steel and fusion smelting of nonferrous metals and alloys, and the technical and economic effects are good.

Characteristic

It has good thermal conductivity and high temperature resistance. In the process of high temperature use, the coefficient of thermal expansion is small, and it has certain strain resistance to rapid heat and rapid cooling.

It has strong corrosion resistance to acid and alkaline solution and excellent chemical stability.

Compared with graphite crucible, silicon carbide crucible has the characteristics of large volume density, high temperature resistance, fast heat transfer, acid and alkali resistance, high temperature strength and high oxidation resistance.

The service life is 3-5 times longer than the clay graphite crucible.

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Well-designed Black Silicon Carbide Sic 95% 1-0mm - Crucible – Anteli , The product will supply to all over the world, such as: Czech, Mauritius, South Korea, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.